TOOLING

Equipment design, prototyping and tool construction

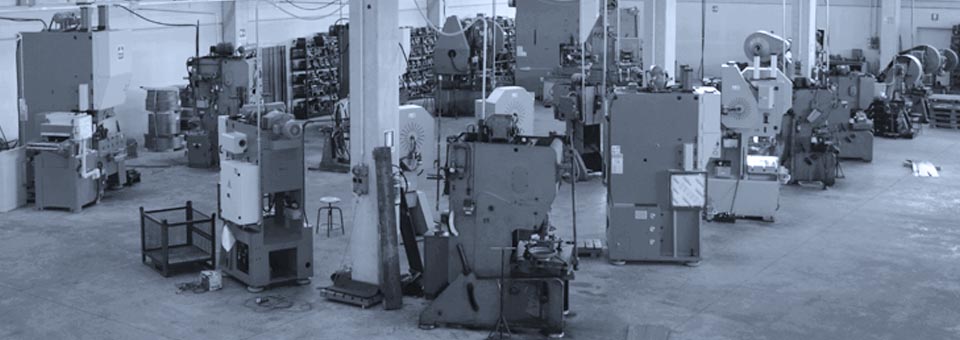

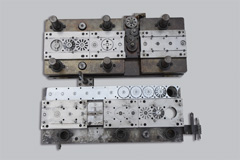

The company has a dedicated tooling department which supports the development of new designs, from the feasibility and improvability

study of the design to the production of the prototypes and the construction of the dies and moulds for series production.

The machines used for tool machining are: 2D CNC machining centres, wire and die sinking EDM, milling machines, lathes, grinders and various

support machinery for tool machining, as well as a furnace for internal tempering of the tools.

2D and 3D CAD files in all major formats can be handled and processed. CAD/CAM modelling is performed using software that has been specifically

optimised for mechanical applications.

Internal tooling carries the considerable advantage of dies and moulds being designed in synergy with production demands so as to create truly

“bespoke” production equipment for each product. It also allows constant and timely intervention should the equipment have any maintenance

requirements, even after the start of production.